A Strategic Approach for a Data Analytics Revolution in Supply Chain Planning

By Ketan Mane, PhD.

Senior Architect, Data Analytics & AI

Today’s supply chains, logistics networks, and manufacturing processes provide tremendous opportunity for automation and data analysis, employing machine learning (ML) and artificial intelligence (AI) to leverage the massive amounts of data readily available from integration with modern sensors, meters, controls, inputs. Data operations, automation, and algorithms enable early warnings, alerts, and forecasts to optimize enterprise systems for speed, efficiency, and readiness.

Data and AI in modern supply chain planning and logistics is an imperative. The mandate for predictive asset maintenance and spare-parts forecasting to prevent interruption to processes at every step maximizes readiness. Inventory optimization—for both raw materials and finished goods—also drives readiness and efficiency by enabling organizations to hold right-sized inventories at the right time and place in order to sense and respond to shifting demands driven by global events and evolving consumer preferences.

So, how do enterprises take advantage of their data to inform and improve supply chain operations?

Understanding the “As-Is” State of Inventory Planning (IP)

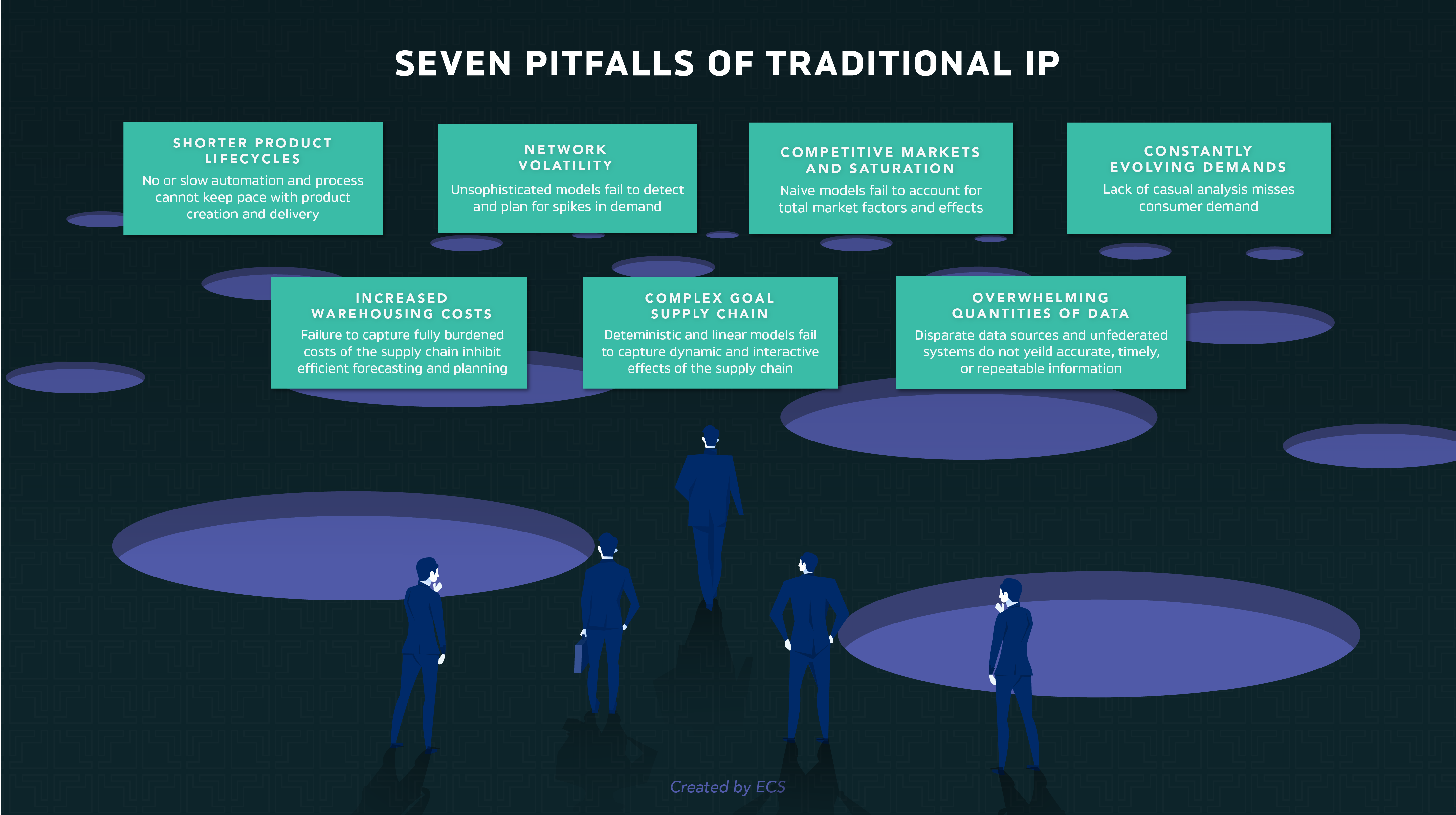

Historically, traditional supply chain planning has struggled to anticipate, detect, and plan for network volatility. Seasonality, changing consumer preferences, and global events like pandemic, wars, and political strife all underscore the importance of both sufficient planning and flexibility to meet unforeseen challenges. Moreover, products are often ephemeral, designed to meet a temporary condition, season, or product lifecycle.

With global supply chains growing more complex and warehouse costs rising every day, simply hedging against demand and supply volatility with large buffer inventories is not a sustainable strategy. Consumer preferences and demand scenarios are diverse and constantly changing. Organizations must be able to read and understand these trends in order to give consumers what they want, when and where they want it.

These challenges drive organizations to seek ways to improve their supply chain planning capabilities. ECS provides solutions that bridge IP pitfalls to maximize efficiencies, productivity, and readiness that:

- Improve the level of sophistication in IP strategy and methodology

- Apply high-performance computing and advanced analytics to leverage vast repositories of data

- Use probability models, statistical inference, simulations, optimization, and economic models to build a comprehensive data program that balances descriptive, predictive, and prescriptive analytics

Improving Supply Chain and Enterprise Resource Planning (ERP)

With the widespread adoption of technology such as point-of-transaction tools, RFID systems, web-based commerce, and social networking, enterprises can capture an unprecedented level of detailed information about customers and their browsing and purchasing behaviors. While many enterprises use this data to improve the effectiveness of sales and marketing programs, the information can also serve to optimize supply chain operations, further strengthening competitive advantage.

In particular, the availability of near-real-time information about how products move—from the supply chain all the way through to customer sales at the SKU level—lays the foundation for an organization’s ability to rapidly anticipate, sense, and respond to changes in the demand pattern. This transformation creates ample opportunity for a new generation of powerful tools that tap into “big data” to manage inventories in ways that were previously impossible. These tools are underpinned by accurate, timely, repeatable analytical processes

Many organizations have struggled to uncover supply chain efficiencies through ERP. At ECS, we use data analytics to help customers configure their planning systems with the right parameters to optimize inventory. Using our advanced analytics capabilities and services, we work with customers to build inventory management systems that achieve orchestrated readiness, enabling organizations to improve upon and overcome:

We leverage data analytics to improve key performance drivers such as service levels, inventory optimization, asset utilization, and working capital. By right-sizing inventory—achieving stock-level reductions of up to 30 percent—organizations not only free up warehouse space and obviate capital expenditure until it is absolutely necessary, but also drive down insurance costs, taxes, and risks associated with obsolescence, pilferage, and inventory damage.

Legacy Systems versus Data Analytics Solutions

Legacy systems rely on human directional forecasting for supply and demand, which often neglects the tremendous predictive utility analytics programs can derive from third-party data including weather, sentiment analysis, and online activity. Analytics can also quantify forecasting risk based on model output confidence levels, centering risk control and mitigation throughout the process.

Legacy systems use rules-based “expert systems” or “expert-in-the middle” approaches, which combine rules with a human decision-maker, to judge important trade-offs, such as:

- Inventory cost vs. Inventory risk

- Pick cost vs. warehouse space cost

- Supplier cost vs. supplier risk

- Buy today vs. buy in the future

- Profit loss vs. opportunity loss

But these solutions are cumbersome, expensive and slow to react to changes. They struggle to replicate success, leading to inconsistent results.

A data and AI approach, on the other hand, constantly learns and evolves. It offers consistent results that improve as the volume of ingestible data grows. Data analytics not only predicts changes, but also detects and adapts to them. Unlike legacy systems, which only operate within the confines of prescribed rule sets, analytics models can explore new and unfamiliar data spaces, deploying several strategies including reinforcement learning and increased prediction risk to meet the challenge of the unknown.

Embracing the Supply Chain Revolution

Predicting supply and demand and defining risk tolerance at the most granular levels is critical to supply chain operations and inventory optimization. As the number of SKUs in any given inventory grows, human-centric and legacy systems will invariably fall behind, but data analytics only improves as the scope widens. Earlier and more accurate predictions driven by data analytics translates into lower prices for inputs, reduced inventory risk, and an ever-increasing edge over competitors.

Don’t panic and don’t wait. A data analytics partner like ECS is a low-risk, low-cost way to migrate your supply chain planning to the cutting-edge. Reach out and talk to an expert today.